Flexible Material Converting

We provide flexible material converting services to help manufacturers and suppliers increase operational efficiency and improve product quality. We specialize in flexible components, but our experienced team has the application expertise and precision converting capabilities to develop a solution for nearly any need. Our partners come to us time and again because we can create custom solutions for challenging applications with tight tolerances and deliver products with exceptional service and support.

Materials

Lakeview Industries is a Preferred 3M™ Converter, giving us access to a wide range of high-quality materials enabling us to provide solutions to fit our customers’ needs. We also work closely with other major materials suppliers to further broaden the options available. Our engineering team has deep experience converting various materials to tight tolerances to help your engineering team select the optimal solution for a given application.

- VHB™ tape (Very High Bond)

- HATS tape (Heat Activated Tape System)

- Belting

- Sheet rubber (EPDM, Neoprene, SBR, Silicone)

- Fabric reinforced sheet rubber (EPDM, Neoprene, SBR, Silicone)

- Foams (Polyurethane, Silicone)

- Microcellular polyurethane

- Pressure sensitive adhesives (PSAs)

- Gasketing materials

- Close cell sponge

- Silicone

- Thermoplastic materials

- Extrusions

Custom design and engineering solutions

Looking for custom flexible materials converting to enhance your next project? Contact us today to get started!

Applications

We specialize in precise flexible material converting for complex projects and can help develop a custom solution for nearly any application. Customers come to us because they know we can help solve their most difficult challenges and develop solutions that improve product quality, performance and reliability. We have experience working with applications including:

- EMI/RFI shielding

- Sealing and gasketing

- Grommets

- Adhesive bonding

- Sound and vibration management

- Insulation

- Thermal management

- Bonding and fastening

- Custom molded solutions

- Injection molded plastics

- Belting

- Integrated mechanical assemblies

Converting Techniques

Lakeview Industries is a full-service converter offering custom flexible materials solutions using a range of converting techniques. We use industry-leading equipment and can achieve tight tolerances for a variety of applications. When it comes to converting flexible materials, we are experts in:

Die Cutting

We offer both flatbed and traveling head die cutting to give our customers greater flexibility in how materials are converted.

Slitting

Cut rolled or sheet materials like films, tapes and foam gaskets into strips of varying lengths and widths to meet exact size specifications.

Rotary Cutting

This technique uses a cylindrical die to cut materials and is ideal for high-volume projects because equipment can produce more cuts at one time compared to flatbed die cutting.

Kiss Cutting

Kiss cutting is used to cut materials without going through all the layers of a stack-up. It is commonly used to cut shapes into materials without damaging the backing liner. Tabs are often integrated for faster installation on our customers’ assembly lines.

Flash Cutting

This process involves CNC-controlled knives and routers that are used to cut materials to different depths and can be highly versatile for unique applications.

Water Jet Cutting

This technique uses a powerful water jet to cut through materials that are too thick or tough for other cutting techniques, such as thick, rigid or dense foams and belting. The absence of heat makes this process ideal for creating a clean edge without damaging the material.

Adhesive Laminating

Join multiple substrates together to create custom adhesive products for unique applications, matching the right material and adhesive for your challenging application.

Skiving

Skiving reduces lead times by cutting bulk buns of foam material to the specified thickness, creating rolls in-house.

Delivering Greater Value

We add value to custom component manufacturing at every stage of the process—from concept to commercial production. Learn more about how we do it.

Molded Components

We have an extensive offering of tooled, molded parts ranging from simple grommets to complex vibration mounts, hoses and custom components. Materials used to create molded components include rubber, plastic, thermoplastic and urethane-based polymers. Whether you need rubber bonding, molded corners and end details or have an extensive overmolding application, we can create the custom solution you need.

Common applications include:

- Arm rests

- Floor mats

- Mounts

- Boots

- Bellows

- Hose/wire clamps

- Assemblies

Extruded Components

We provide both tooled and custom extruded components in rubber, sponge and thermoplastic materials. Our value-added extrusion capabilities include adhesive lamination, cut-to-length, splicing and bonding and sub-assembly to enhance efficiency throughout the production lifecycle.

Common applications include:

- Window, door and panel seals

- Enclosure seals

- Edge trims

- Conductive applications

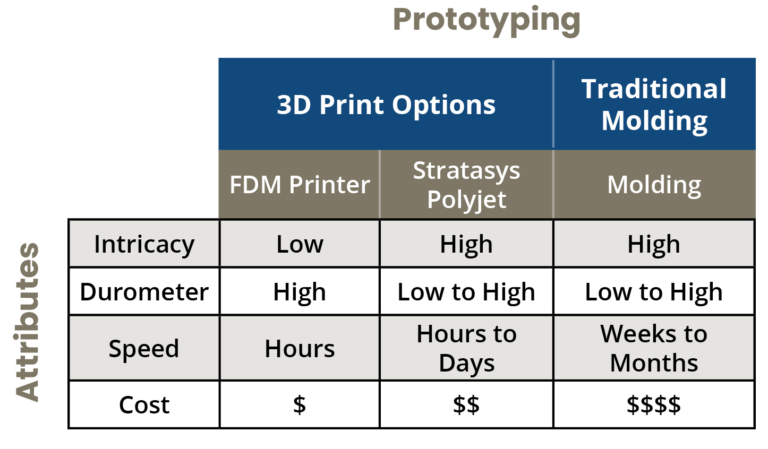

3D Printing & Prototyping

Accelerate the product design cycle and get parts into production faster with our 3D printing and rapid prototyping services. Design engineers can simultaneously print multiple concepts, reduce rework and make it easier to adjust designs with minimal downtime. We offer two printing options, a Stratasys PolyJet™ printer and an FDM printer, and we can create multiple durometers on a single print, including plastic. Our 3D printing services enhance efficiency in your operation by making it faster and easier to complete concept validation, fit checks and functional tests.

Assembly & Kitting

We offer assembly and kitting services to help manufacturers streamline the production process and get products into their customers’ hands faster. Our full-scale solutions allow manufacturers to combine parts into a single SKU to minimize packaging costs, simplify inventory management and streamline the shipping and delivery process. Combined with our other custom flexible material converting capabilities, our assembly and kitting services make Lakeview Industries a one-stop shop to streamline your manufacturing operation.

Industries Serviced

We are proud to work with manufacturers and suppliers across a wide range of industries and markets. Some of the industries we work in regularly include:

Aerospace

Agricultural Equipment

Automotive

Construction Equipment

Consumer Goods

Electronics

HVAC

Medical

Recreational Vehicles

Our Quality Commitment

Speed To Market

We understand the importance of getting your new products out to the market quickly. We’ll work with your engineers and designers to help expedite development and work along with procurement to meet production requirements.

Competitive Pricing

We work efficiently to reduce overall project costs and source quality materials at competitive prices, saving you money.

Customer Relationships

We pride ourselves on long-standing customer relationships. We have worked with many of our customers for over 40 years.

Innovation

Being innovative is critically important to being mutually successful with our key customers. We continue to research new materials and process capabilities.

Get a Sample

Need too see a material in person? Get one shipped to you in as little as 24 hours.

Contact UsTalk to an Engineer

Set your project in motion by discussing your needs with an engineering consultant.

Contact Us