Solve your most complex manufacturing challenges

Lakeview Industries develops custom converting solutions for manufacturers across a wide range of industries. Our short turnaround times, superior quality and ability to produce solutions to specified tolerances help our partners increase manufacturing efficiency, improve products and control costs. By providing precision converting services and excellent design and material selection support, we help OEMs and suppliers solve their most complex challenges to achieve operational goals.

Mechanical Solutions

We offer a wide range of mechanical solutions with custom components that enhance the performance, efficiency and durability of industrial applications. We’ve produced debris shields, protective belting in a variety of thicknesses, chutes, mechanical assemblies like steering arms, brake assemblies and much more. We can also die cut, slit or otherwise convert pressure sensitive adhesive (PSA) tapes like 3M ™ VHB™ tape, adhesive transfer tape and more for bonding and fastening applications. Whether an application calls for a complex assembly or a single extruded part, we can provide the mechanical solutions necessary to drive the next wave of industrial innovation.

Sound and Vibration Management

Noise, vibration and harshness (NVH) and buzz, squeak and rattle (BSR) issues are as common as they are unwanted. Finding solutions to these problems can enhance the user experience and provide welcome relief to those working on industrial equipment. Whether you’re looking to quiet cabin or engine noise in automotive applications, eliminate squeaks in an HVAC system, or just want to turn down the volume on noisy equipment, Lakeview Industries can help. We convert a range of materials for NVH/BSR applications, including a variety of open- and closed-cell foams, rubbers, silicone products and other materials. From isolator mounts to custom gaskets, our custom solutions provide needed acoustic insulation, reduce vibration and eliminate unwanted noise. We can also laminate adhesives onto NVH/BSR solutions to reduce assembly time and eliminate downstream manufacturing processes.

Molded Solutions

We specialize in molded solutions made from a variety of rubber and plastic materials, including silicone, thermoplastic and urethane-based polymers. We can also create extrusion products with both tooled and custom profiles in rubber, sponge and thermoplastic materials. With our converting capabilities, we can customize molded or extruded products to exact specifications to specified tolerances. Applications for our molded solutions include window, door and panel seals, enclosure seals and edge trims, arm rests, floormats, mounts, boots, bellows, hose/wire clamps and assemblies.

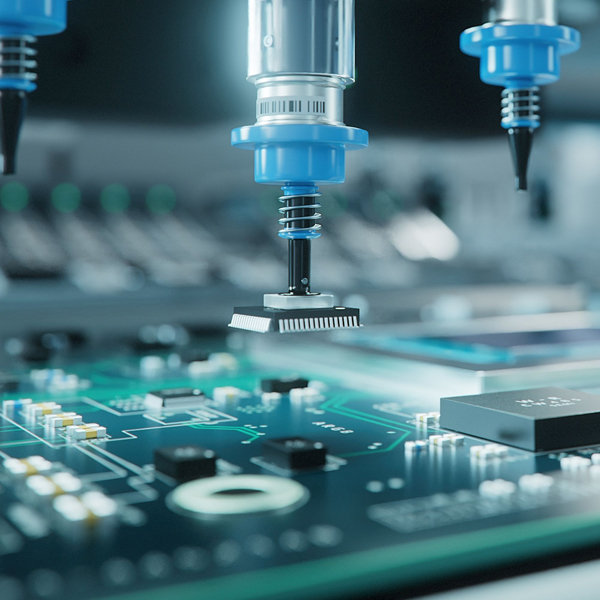

EMI/RFI Shielding and Thermal Management

As technology evolves, more industrial and consumer products are entering the internet of things (IoT) space and the power density of batteries and other energy storage solutions is increasing. With increased power and functionality, OEMs need to find ways to protect sensitive components from electromagnetic interference (EMI) and radio frequency interference (RFI), as well as develop adequate thermal management solutions. We regularly create effective EMI/RFI and thermal management solutions to enhance products and protect users. We can convert thermally conductive cushioning materials for battery assemblies, durable adhesives that can withstand significant temperature cycles and a range of solutions to protect against thermal runaway events.

Sealing, Gasketing and Grommets

Whether an application calls for waterproof component-to-component bonding or environmental seals to achieve a target ingress protection rating, we have the custom solutions to meet project requirements. We can create custom grommets, gaskets and other types of sealing solutions to meet a range of application needs. We can also produce extruded components and custom “window gaskets” to allow for greater design freedom and functionality. We work closely with our partners to understand requirements and can suggest the most efficient, cost-effective solution to solve complex sealing or gasketing challenges.