Custom Component Solutions for Mechanical Applications

Our custom mechanical solutions solve challenges for a wide range of industries and applications. From complex assemblies to protective belting products, pressure sensitive adhesives and more, we help manufacturers speed up product development and improve manufacturing efficiency while enhancing end products.

Belting

We offer a wide range of mechanical solutions with custom components that enhance the performance, efficiency and durability of industrial applications. We’ve produced debris shields, protective belting in a variety of thicknesses, chutes, mechanical assemblies like steering arms, brake assemblies and much more. We can also die cut, slit or otherwise convert pressure sensitive adhesive (PSA) tapes like 3M ™ VHB™ tape, adhesive transfer tape and more for bonding and fastening applications. Whether an application calls for a complex assembly or a single extruded part, we can provide the mechanical solutions necessary to drive the next wave of industrial innovation.

We can use water jet or die cutting equipment to cut belting materials into exact shapes with tight tolerances, and we can work with a variety of belt thicknesses. We specialize in working with extremely durable RMA Grade 2 belting materials made from SBR blends. We offer options for super abrasion resistance (SAR), oil resistance (MOR) and a variety of thicknesses and widths. We can also laminate adhesives onto belting materials, add holes or otherwise convert materials to best suit downstream manufacturing and assembly processes.

Our value-added services include kitting and subassembly services to help manufacturers focus on what they do best. We can also screen print onto belting materials or emboss solutions to feature company logos or other graphics for a branded experience.

Benefits of Our Custom Belting Solutions

- Durable protection for rugged application environments

- Extremely reliable, durable materials

- Branded product experience

- Faster assembly

PROJECT HIGHLIGHT:

Durable, Cost-Effective Solutions for Rugged Environments

We’ve developed countless custom belting solutions that not only protect products from harsh environments, but add significant value for OEMs. For example, we assisted in developing a draper shield for a harvester combine. Our solution replaced an old polyurethane component and met customer requirements for the application at about one third of the cost. We’ve also developed ladder rungs for heavy equipment. These components replaced metal rungs which were constantly damaged by environmental hazards (i.e., large rocks, etc.). The belted rungs simply flex out of the way of incoming debris and were an effective replacement for the customer’s masticated rubber materials, providing greater durability and superior UV resistance.

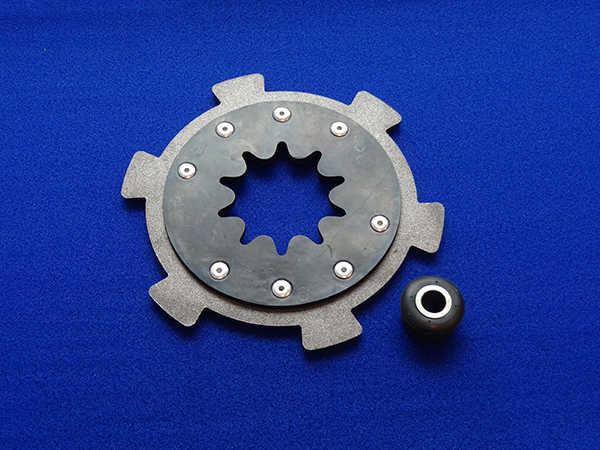

Mechanical Assemblies

We bring extraordinary value to manufacturers of all shapes and sizes with our mechanical assembly solutions. We can produce and assemble multiple individual components to create truly custom solutions for things like brake assemblies, equipment steering arm assemblies, and much more. Whether an assembly involves a few simple pieces packaged together or multiple complex components that have to undergo multiple converting processes, Lakeview can help. We create custom components for mechanical applications that enhance end products and our assembly services save manufacturers time and space in their manufacturing facilities.

Benefits of Our Mechanical Assembly Solutions

- Faster product development

- Greater efficiency by eliminating downstream assembly processes

- OEMs save space in manufacturing facilities

- Durable custom components for mechanical applications with tight tolerances

- Lower transactional costs (fewer POs, invoices, shipments, etc.)

PROJECT HIGHLIGHT:

Zero-Turn Mower Steering Arm Assemblies

Lakeview Industries is proud to work with a major lawnmower OEM to provide a complete steering arm assembly for a zero-turn mower. The project began with Lakeview producing only the rubber grips for the users’ hands. From there, our partners trusted us to take on more and more and we now produce the entire steering arm assembly including the arms, the linkage, weldments, and components molded from plastic or rubber that gets bolted onto the mower. We also provided Pantone color matching to conform with the OEM’s desired brand experience. Our mechanical assembly services help this customer save time and control costs while ensuring reliable quality and durability for this critical assembly.

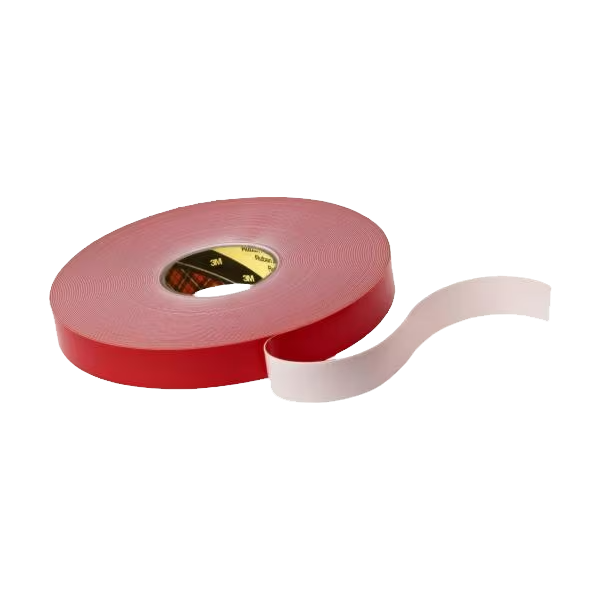

Bonding and Fastening

Whether a project calls for permanent or temporary bonding, we can create custom bonding and fastening solutions to meet nearly any need. We regularly develop solutions for permanent or temporary bonding applications using adhesive tapes to eliminate mechanical fasteners like screws or rivets. We convert pressure sensitive adhesive (PSA) materials like VHB tape, adhesive transfer tape, electrical tape, vinyl tape, cloth tape, thermally insulating tapes, packaging tapes and many others. We cut these materials into exact shapes and can add liners with registration marks or other features to facilitate faster assembly and a better user experience. We can also provide extruded components and laminate them with adhesives to create ready-to-assemble sealing solutions for a range of applications. We are one of the few 3M™ Preferred Converters in the country with access to 3M Automotive HATS tape (Heat Activated Tape System).

Our solutions are used for sealing critical components and bonding individual parts together to make products lighter and faster to assemble while helping to control costs. From panel assemblies to internal component bonding, watertight sealing applications and more, we have the bonding and fastening solutions to take products to the next level.

Benefits of our Bonding and Fastening Solutions

- Custom converted pressure sensitive adhesives

- Permanent or temporary bonding applications

- Waterproof seals and enhanced ingress protection

- PSA tapes are typically lighter than mechanical fasteners

PROJECT HIGHLIGHT:

Print Pocket Attachment Yields Big Benefits

A manufacturer in the commercial and industrial enclosure industry wanted to attach a print pocket inside of an enclosure using 3M™ VHB™ tape. We developed a custom converted solution to maintain enclosure integrity by eliminating drilled holes, reduced costs by eliminating welding and assembly time, reduced the risk of worker injury and increased overall flexibility in the enclosure. Our solution not only met the customer’s application requirements, but provided operational benefits to move their entire manufacturing operation forward.